From jute manufacturing to production, we strive for perfection

Upholding a century of trust

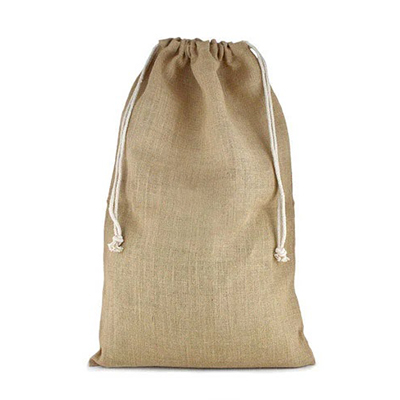

Committed to bringing you the finest jute goods

A comprehensive range of high-quality jute products

The production is focused on environment-friendly methods

Previous slide

Next slide

Commitment and excellence in serving your jute-based needs.

- ABOUT THE COMPANY

100 years of excellence in production

Originally The Reliance Jute Mills Company Limited (“the Company”) was incorporated on 25th October, 1906 under the Indian Companies Act, VI of 1882 which owned the Jute Mill situated at Bhatpara, 24 Parganas (North), on the bank of the river Hooghly in West Bengal and was running under the management of Jardine Henderson Limited (a Company in U. K.). During the year 1963, the Mill was taken over by Indian Management i.e. Kanoria Family. The name of the Company was changed as The Reliance Jute & Industries Limited (“the Company”) with effect from 20th April, 1971.

Subsequently, under a Scheme of Arrangement between the Company and other two Companies viz. RJM Fibre Industries Limited and RJM Investments Limited, Jute Unit of the Company was transferred to RJM Fibre Industries Limited and Investments Division was transferred to RJM Investments Limited vide an Order passed by Hon’ble Calcutta High Court on 17th April, 1989.

- WHY JUTE

Jute is the choicest fiber. Here's why!

Environment Friendly

Jute is an environment-friendly raw material with an early appeal and a wide range of applications. Jute cultivation consumes 15 tonnes of CO2 and releases 11 tonnes of oxygen.

Sustainability

Jute cultivation heals nature, not harm it. As the world adopts sustainable practices, jute products come to the forefront.

Health & Safety

Jute fiber is recyclable and 100% biodegradable. Therefore, manufacturing and producing jute maintains the highest level of health & safety. In addition, the fiber can be spun into many products.

Financials

The jute sector employs lakhs of workers across the country, and it helps in sustainably producing jute products for sale.

-Efficiency by the workers

method of Jute Processing

The jute plants are harvested, and then the fibers are extracted by a process called retting. In this process, moisture and microorganisms are used on plants to dissolve the cellular tissues that surround fiber bundles. This helps in separating the fiber from the stem. The retting process also involves bundling and immersing the jute in water.

After this process, the fibers are stripped. Then, the non-fibers are removed, and the fibers are separated from within the jute stem. Finally, they are dried in the open air, and the resultant fiber is used to produce products like jute yarn, geo-jute, handbags & shopping bags, etc.

After this process, the fibers are stripped. Then, the non-fibers are removed, and the fibers are separated from within the jute stem. Finally, they are dried in the open air, and the resultant fiber is used to produce products like jute yarn, geo-jute, handbags & shopping bags, etc.

- Our Products

Our incredible products