Our Products

Description of Jute Products

Jute is a long, soft, shiny fibre that can be spun into strong threads, coarse and fine. It is produced from flowering plants in the genus Corchorus which is in the mallow family Malvaceae. This fibre is natural, environment friendly and sustainable due to its woody composition. It needs very little maintenance while growing.

India is the world’s biggest producer of jute followed by Bangladesh. Jute is primarily grown in West Bengal, Odisha, Assam, Meghalaya, Tripura and Andhra Pradesh.

Usage

The major manufactured products from jute fibre are :

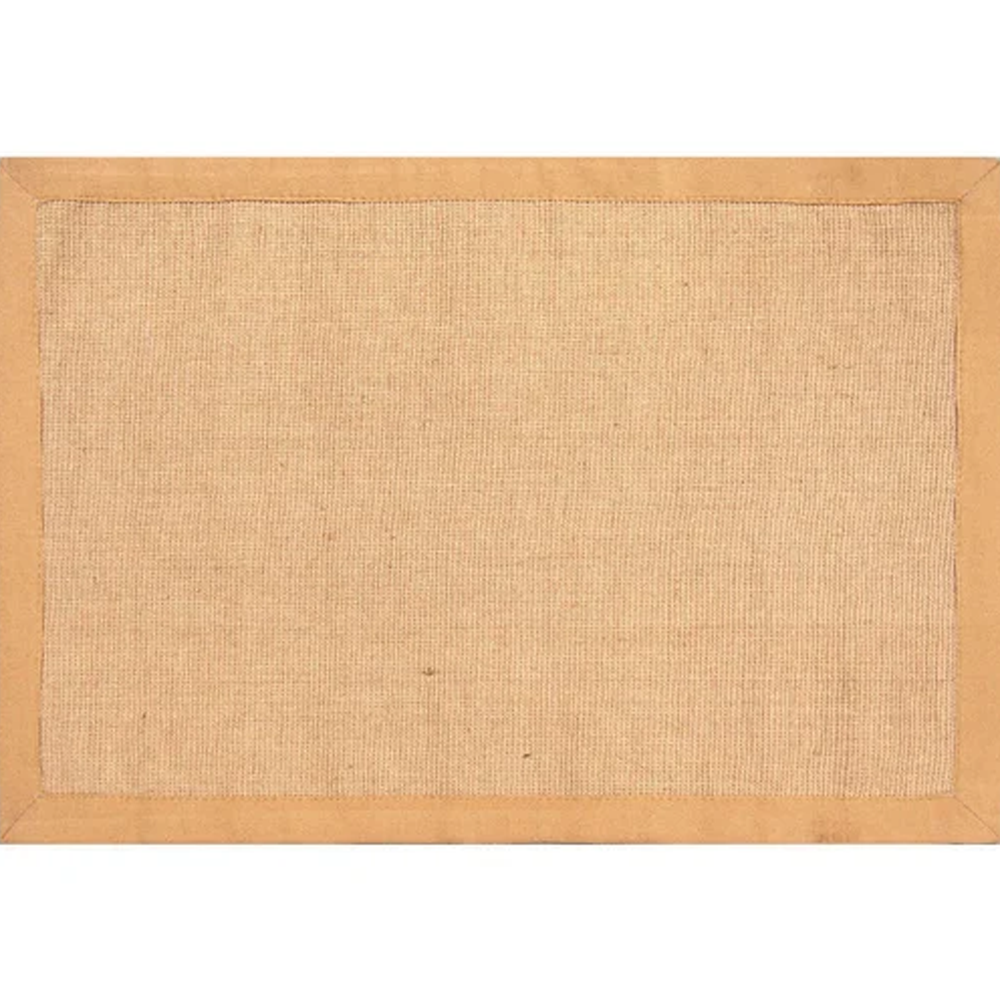

Yarn and twine, sacking, hessian, carpet backing cloth and as well as for other textile blends. It has high tensile strength, low extensibility and ensures better breathability of fabrics. Researchers found that jute has been used for textile production since 3rd millennium BC, mainly in Indus valley civilization. A number of household and commercial items are produced from this fibre. It can be used to make items such as rope, twine, rugs, chair covers, hessian cloth and food grade bags for cereals, cocoa, cashew packing and sugar. Jute geo-textiles is used for road construction and filtration, jute soil saver us used on hill sloped and river banks to protect soil erosion and for plantation, It is also used in home décor for example as carpets, curtains, shoes, shopping bags and various diversified products. During World War I, jute sandbags were shipped from Bengal to the trenche3s. In fact this hazard free natural fibre is a bless on the earth.

Yarn and twine, sacking, hessian, carpet backing cloth and as well as for other textile blends. It has high tensile strength, low extensibility and ensures better breathability of fabrics. Researchers found that jute has been used for textile production since 3rd millennium BC, mainly in Indus valley civilization. A number of household and commercial items are produced from this fibre. It can be used to make items such as rope, twine, rugs, chair covers, hessian cloth and food grade bags for cereals, cocoa, cashew packing and sugar. Jute geo-textiles is used for road construction and filtration, jute soil saver us used on hill sloped and river banks to protect soil erosion and for plantation, It is also used in home décor for example as carpets, curtains, shoes, shopping bags and various diversified products. During World War I, jute sandbags were shipped from Bengal to the trenche3s. In fact this hazard free natural fibre is a bless on the earth.

Characteristic

Jute can be recycled for its bio-degradable nature. Jute goods like mats, bags and rugs that have been too old to use anymore can be turned into compost for garden. As well as having natural UV protection, jute grows without the use of fertilizers and pesticides thus free from health hazards.

Cultivation

A warm and humid climate, plenty of rainfall and well-drained, loamy soils are needed for jute cultivation. The interesting thing about jute growing is that fertilisers and pesticides are barely needed. They are subjected to ‘retting’ after the stems are harvested from the plant, whereby they are submerged in slow running water for 10 to 30 days in order to allow bacteria to dissolve the gummy materials holding the fibres together. After this in a method called ‘stripping’, the non-fibres matter of jute is scrapped off and then the fibre is separated by beating with a paddle of the stem. The separated fibres are then washed, dried, graded and sent to jute mills to be further processed for the production of jute yarn. The yarn is then used for various jute products to be produced.